We place Mechanical/Electrical/Electronics Engieers for the required jobs to companies which helps companies for flexible resource planning. We train the staff based in the requirement before deployment

20+ years of experience on various topics of Mechanical and Product Engineering

Understanding the customer requirement with ease

ENGINEERING SOLUTIONS

We have very good experience working on Electro Mechanical products such as power tools, hand held instruments, health care products, manual farming tools, etc.

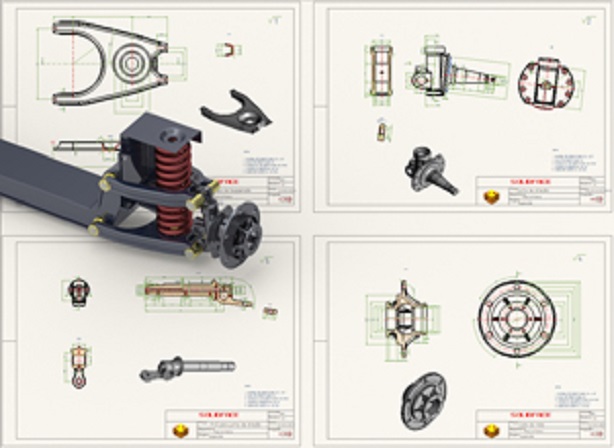

We also support PCB scheamtic design, CAD design, wire routing, component design, Assembly design and manufacturing drawings creation, BOM management, Engineering Change management, feasibility products, etc.

We create 3D models in CAD and make the prototypes in 3D printing/CNC machining/sand casting based on the requirements. We also take care of the soft and hard tool development for the component manufacturing. We have very good vendor base tosupport in development of various metal, sheetmetal, plastic, rubber prototype components.

show more...

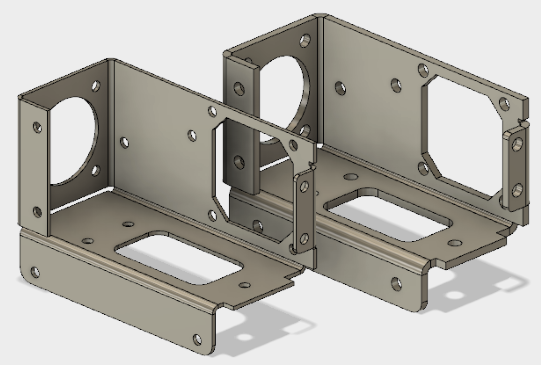

We have very good expertise and experience creating manufacturing drawings for assemblies, components (Welding structures, Sheetmetals, Machied components, etc) with required GD & T and dimensional tolerances.

We prepare the drawings consindering customer standards and guidelines; provide only required dimensions and tolerances based on the manufacturing approach such as wirecut/flamecut/CNC machining or manual machining etc. Sheet metal drawings are prepared considering the manufaturing steps of each component so that drawing reading is very easy and effective.

Mating surfaces, holes and BOM is very important aspect of manufacturing drawing creation. We are well versed with this topic and execute the project with great efficiency and quality.

show more...

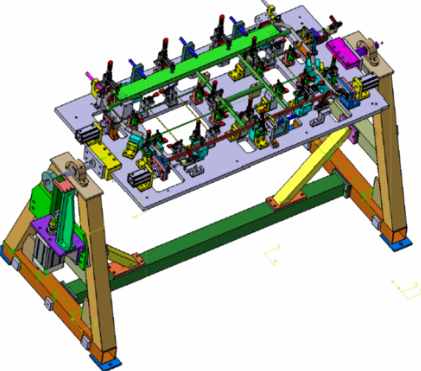

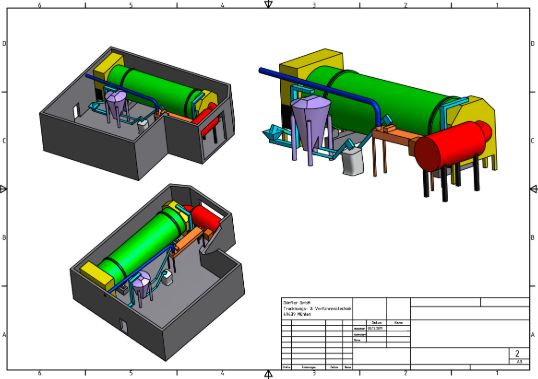

Close to 7 years of working with KUKA for Jigs and Fixtures for FORD cars and Daimler cars BIW mainly. Worked on Idea based FIDES and Catia V5 for Daimler.

Have complete experience working on various kind of components such as welding fixture, checking fixture, Grippers, Base frames, weld study and weld line definition, etc.

Preparing the complete CAD documentation with assembly, parts and BOM in customer standards. Great experience in creating detailed drawings for manufacturing whole lot of machined components, welding frames, shims, Mylars, etc.

show more...

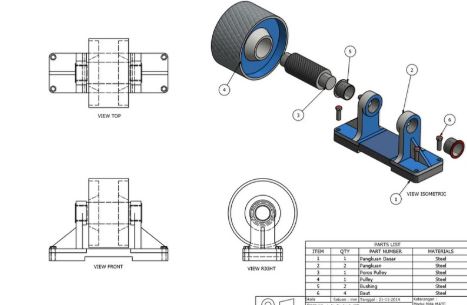

We create 3D models with the Skelleton model concept and top down approach. So that the model tree can be maintained without any hassels. We also create master model concept wherever needed to save the time of CAD conversion project.

Associated drawings are created with the model dimensions. With this CAD documentation will not will have fake dimensions

Both 3D and 2D files are associated and uploaded to PLM system such as Teamcenter, Innovia, smarTeam, Windchil, etc.

show more...

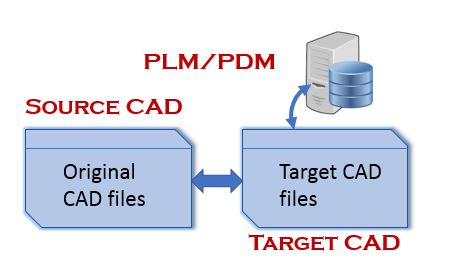

We migrate the 3D models, Drawings both parametrically and non parametrically. In the recent development we also support in remastering the files after parametric migration using tools such as Elysium or CMM (Content Migration Manager) tools.

We have a proven methodology and approach for mass migration projects; in general we migrate all old (archieved or non live data) using our own built-in tools non parametrically in quick times which converts the data 95% data accuracy. We also have checker tools which check for the correct migration and give report on which files migrated with errors. Those files can be fixed manually, saves lot of time and gives great result.

We also migrate metadata from old PLM to new PLM system. Also download & upload data using mass processing tools which save lot of time. We change the status, provide ownership based on the reference PLM.

Convert CAD design from one CAD to another CAD system which involves creating 3D models from 2D drawings (paper drawing or digital drawing), recreate the 3D models and drawings in different CAD system or with different customer specific method, etc.

We also create customer model or simplified models and exchange the CAD data between supplier and OEMs. We support CAD data Exchange formajor OEMs from Europe such as VW, Audi, Ford, GM, Daimler, etc.

We check the files with checkmate and Qcheckers to meet required quality standards. We have very good experience working on multiple CAD platforms and execute the projects with great efficiency.

We support in complete documentation for the full product with refernce to Engineering processes, main and Sub systems, components, materials, suppliers, design historym changes, etc.

We support in developing user know-how documentation; e-Learning guides to provide overview on the product with structured write-ups;animations, etc.

We also support in preparing animations for assembly sequence, parts changes while maitenance of the product/repair, funtioning of the products, etc.

With our great 20+ years of experience working on various products we are able to break-down the entire product with respet to key functions and sub functions. With our funtion to cost matrics we are able to derive which functions we can optimize the save the cost.

It is quite natural to do over design with the first version of the product launch to ensure product does not fail in the field. Once it is proven we take the optimization task with our independent view to save the cost for the product.

we have team of eperts who are certified to carryout VA-VE. With them the products are scanned with the alternate approach and looked thoroughly for further betterment on the cost without compromising the quality of the products.

We have facility to dis assemble and understand the structure, material, critical components design, assembly method, etc. This observtions are noted in a professional document with step by step photos to understand the competitor products

We also test the products funtionally in a lab or in the field to understand the true specification of the product and report to customers in a simple way which helps in creating Requirement Specification of the new products.

We have good vendor connect to benchmark/test various aspects of the product and understand insights of each function. We also support Electronics benchmarking with clear development of BOM.

We have good vendor base locally who support us in building prototypes such as 3D printing (FDM), Rapid prototyping, Silicon mould components, CNC machined components in Aluminium/plastic, etc.

We also have vendors to print the Gerber files (PCBA layouts); we also assemble the complete product and test before shipping to customer so that there is much visibility on the components manufactured and overall functioning of the products.

We also support in development of soft tools which serves the perpose for small quanity of products at least in the beginning. The components will be par with final components but cost wise 25% to the final hard tooling cost.

BENIFITS OF ASSOCIATING WITH US

Professional Project Management

Regular Status update

Great commitment

Highly Passionate and flexible Team

Complete support not a piece work